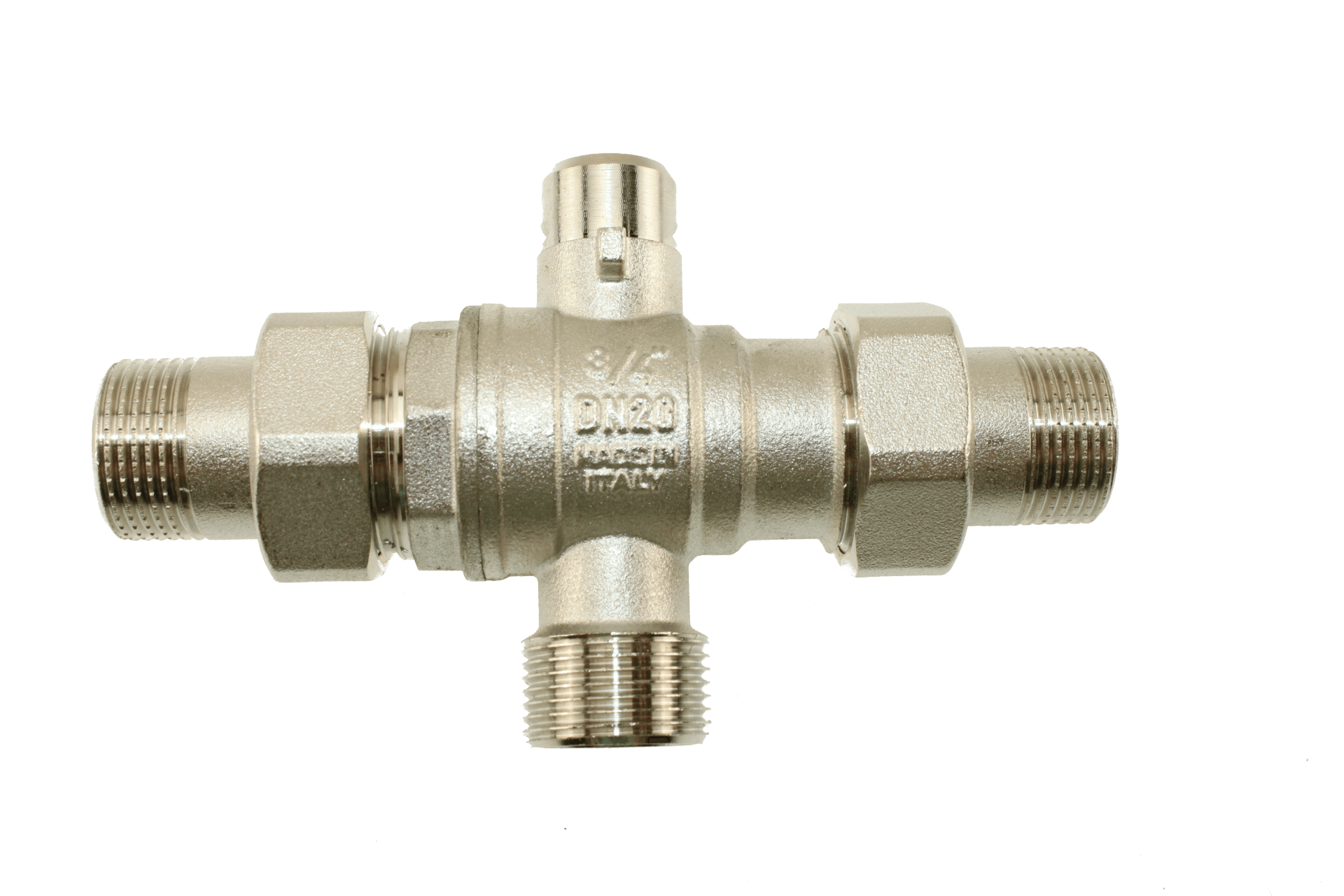

Ball valve 6 fold

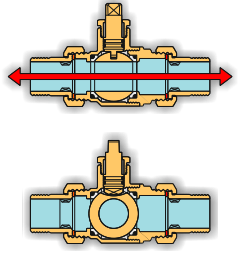

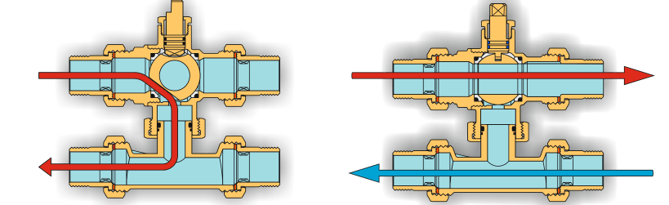

This ball valve can be

used for, for example, district heating or heat pump systems

Technical data:

Working temperature: -10°C to 100°C

Max pressure: 16Bar

Max differential pressure: 2 Bar

Connection DN: 3/4"

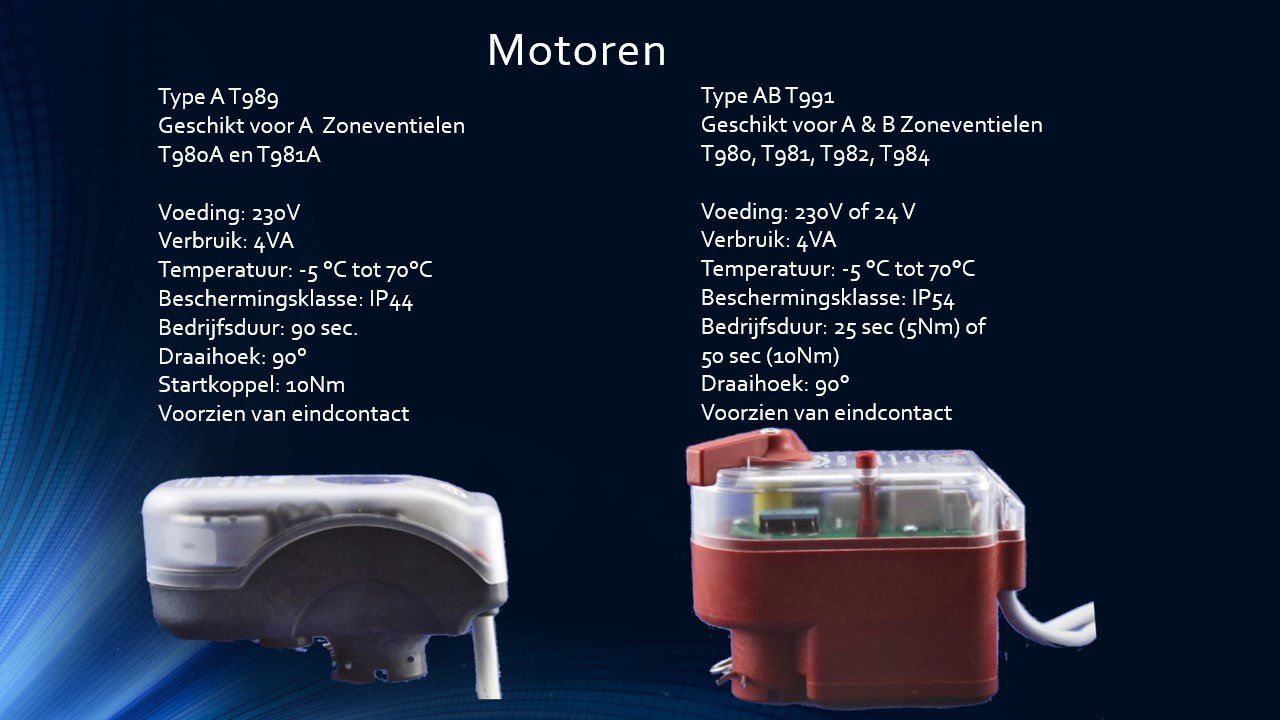

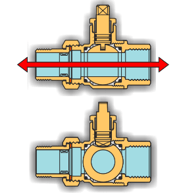

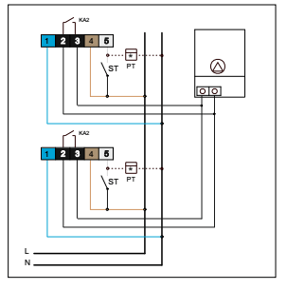

T989A Motor for Zone Valve A

T991AB23025 Motor voor Zoneventiel A of B 230V 25sec

T991AB23050 Motor voor Zoneventiel A of B 230V 50sec

T991AB24 Motor for Zone Valve A or B 24V 50sec

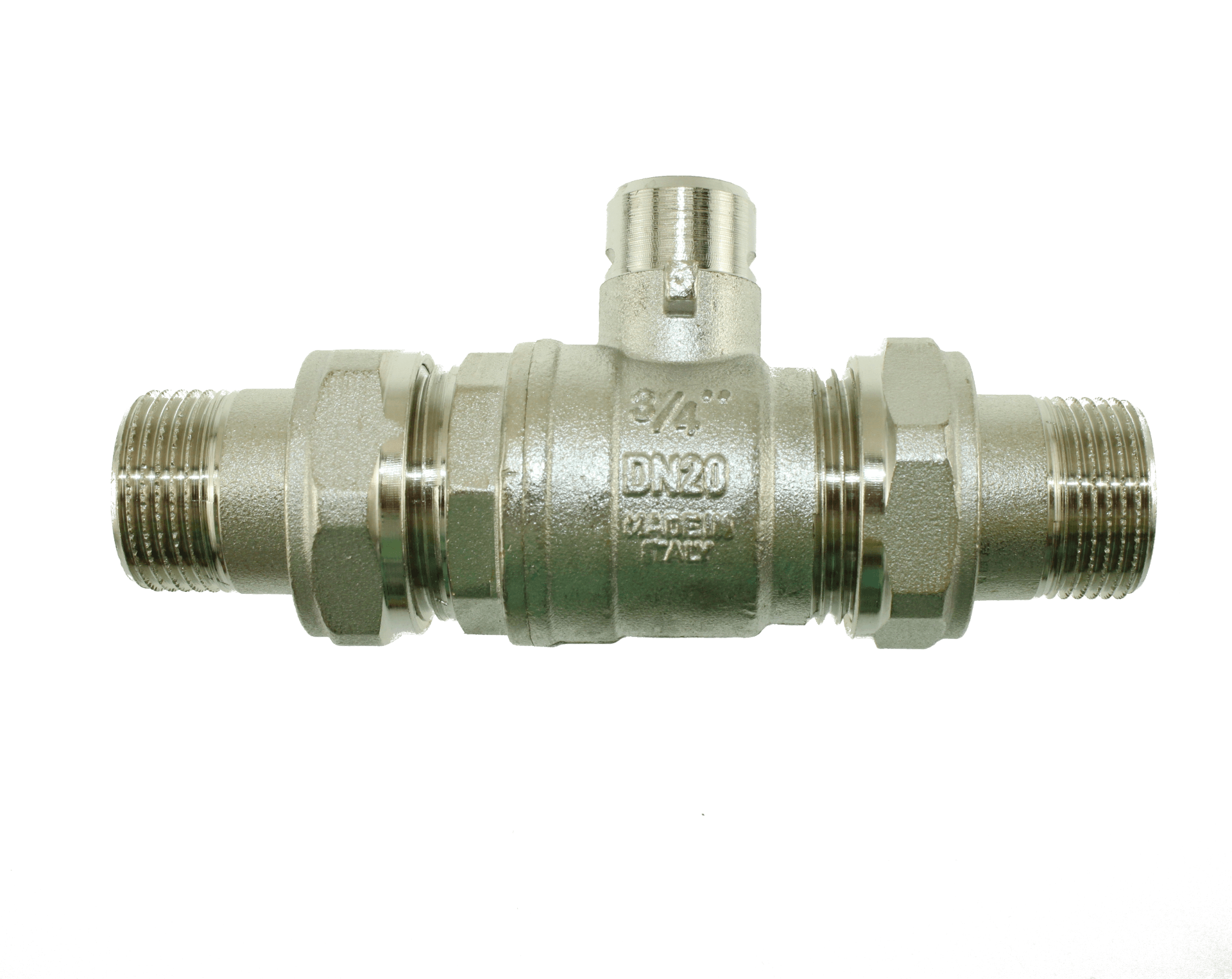

T980A0505 Zoneventiel 2V ¾”

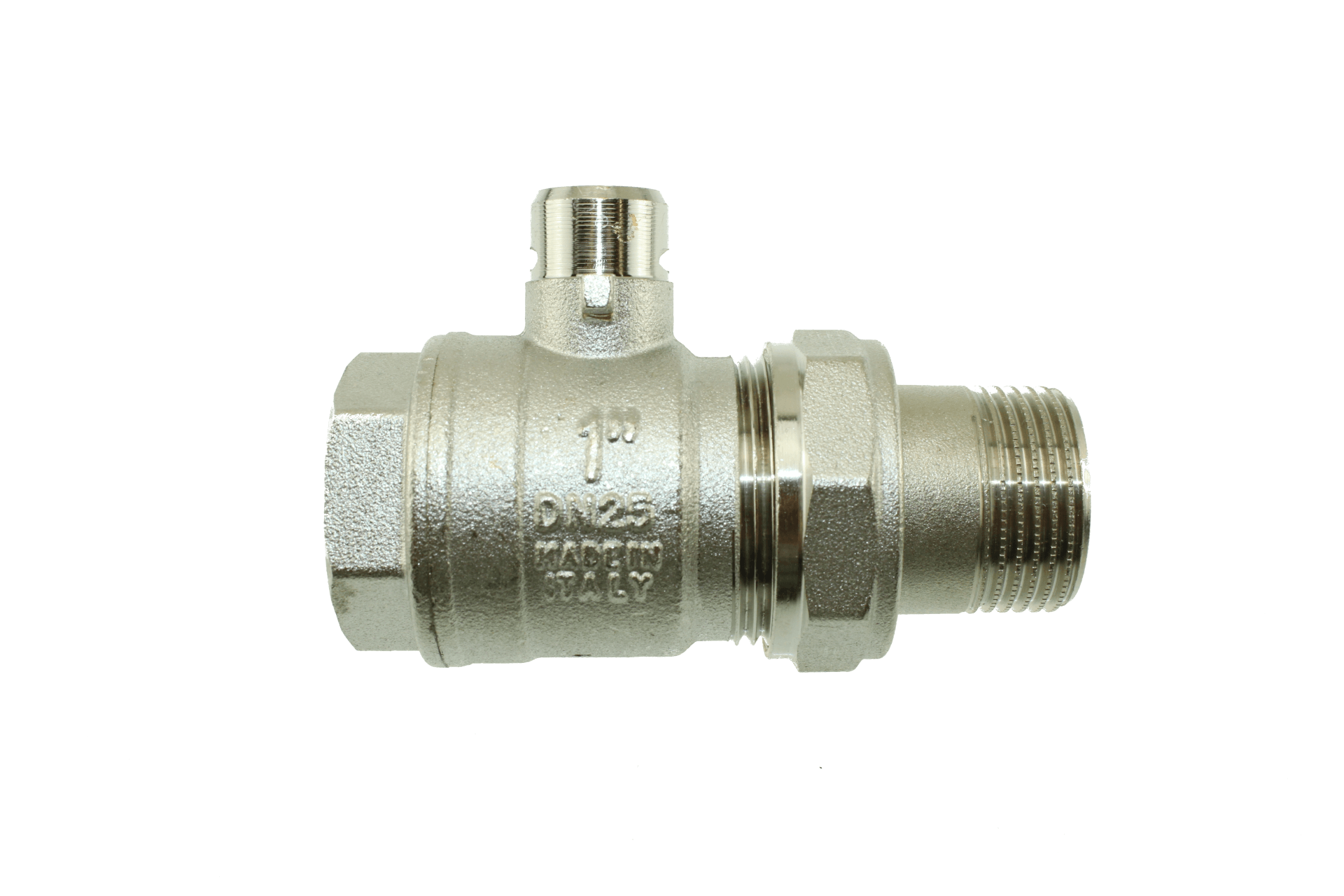

T980A0606 Zone valve 2V 1”

T971A0505 Zoneventiel 2V ¾”

T981A0606 Zoneventiel 2V 1”

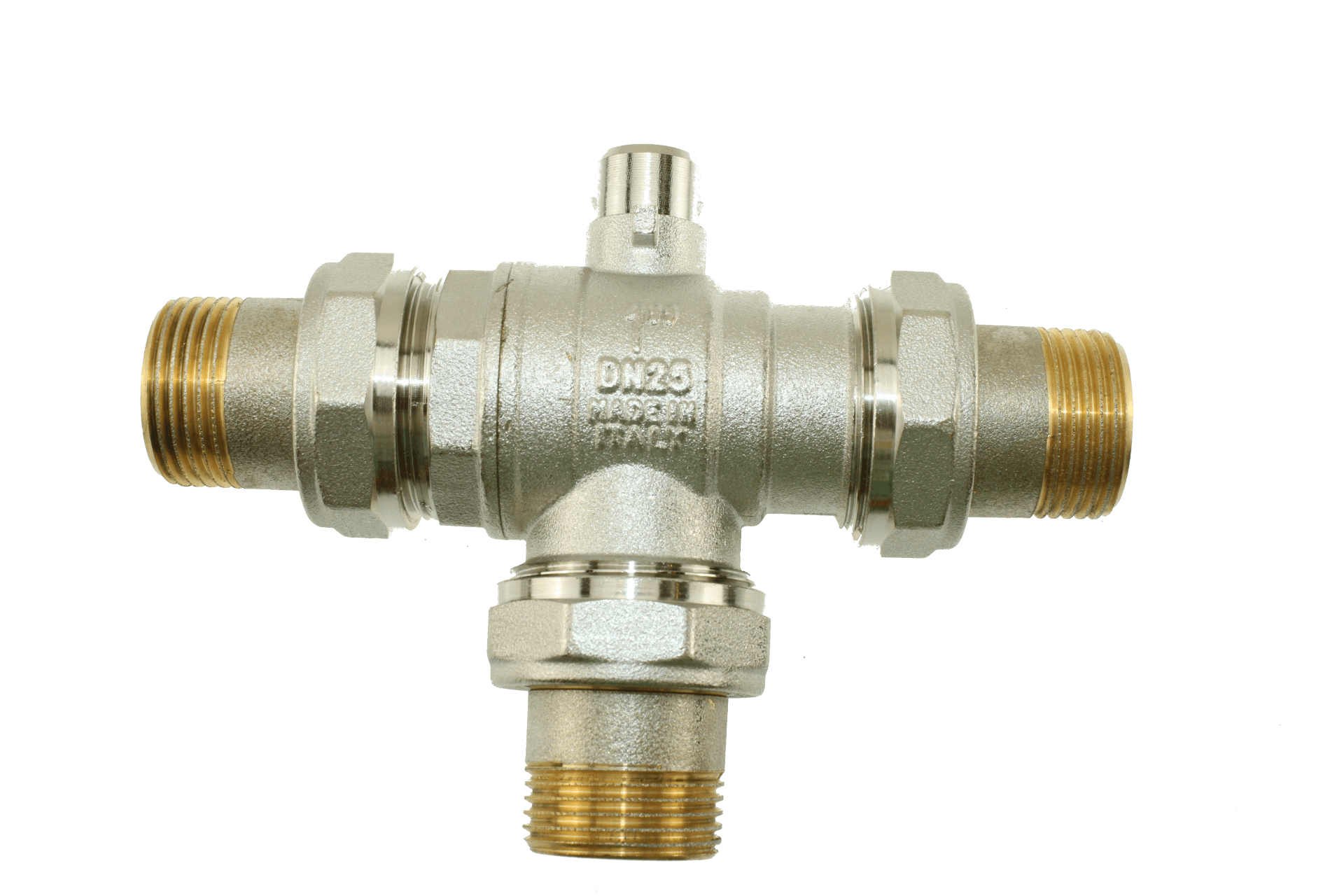

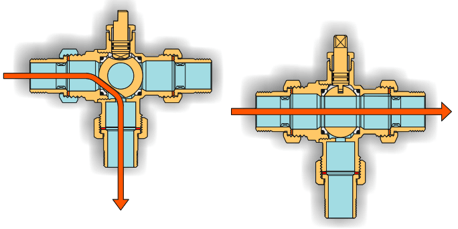

T982B0505 Zoneventiel 3V ¾”

T982B0606 Zoneventiel 3V 1”.

T984B0505 Zoneventiel 3V ¾”

T984B0606 Zoneventiel 3V 1”

Also available with a 22mm compression connection for direct connection to a copper pipe.

T700A2222 Zone valve A 2V with 22mm compression connection

T700B222222 Zone valve B 3V with 22mm compression connection

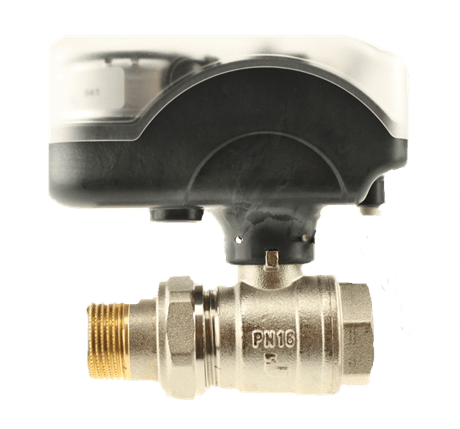

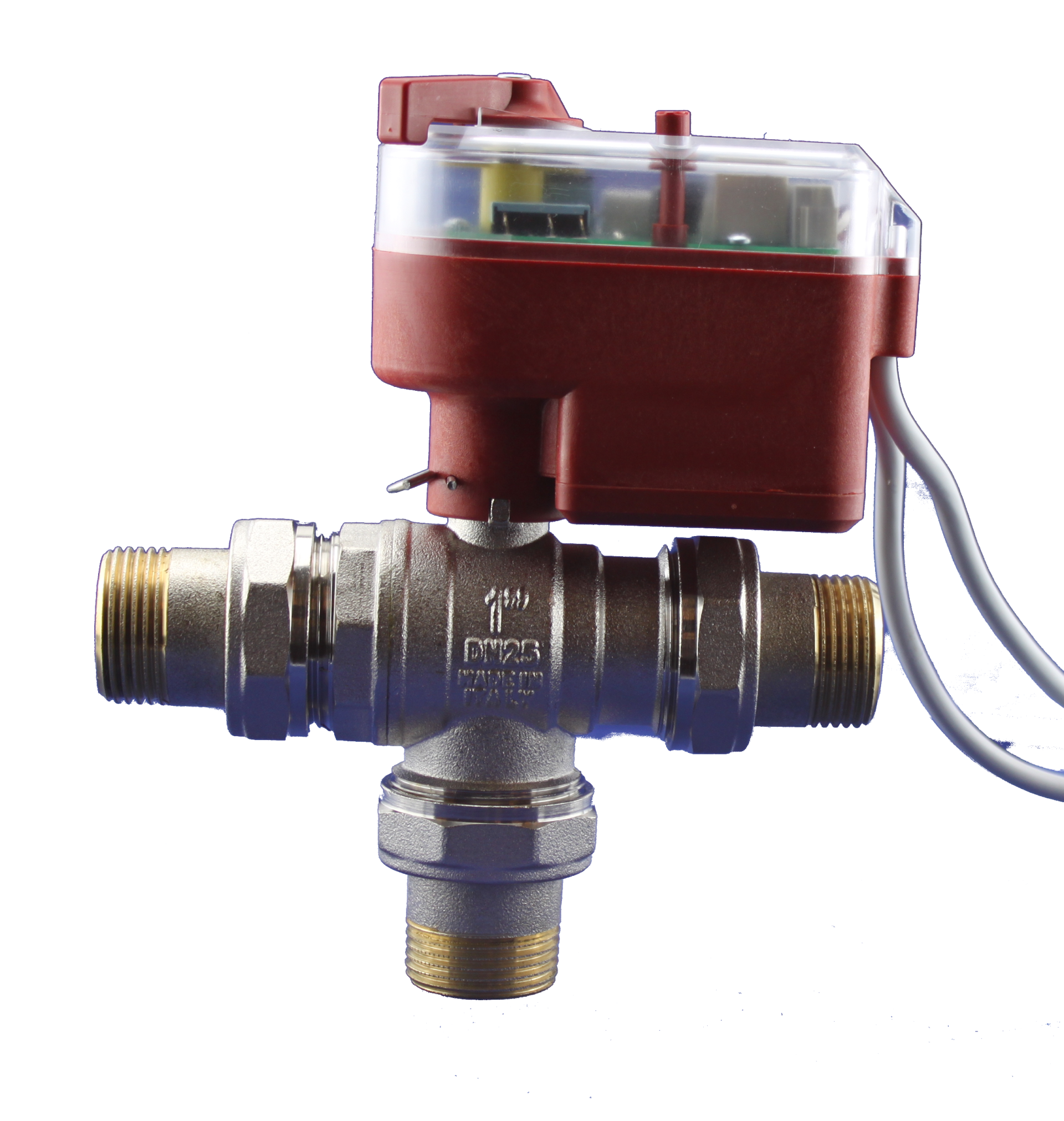

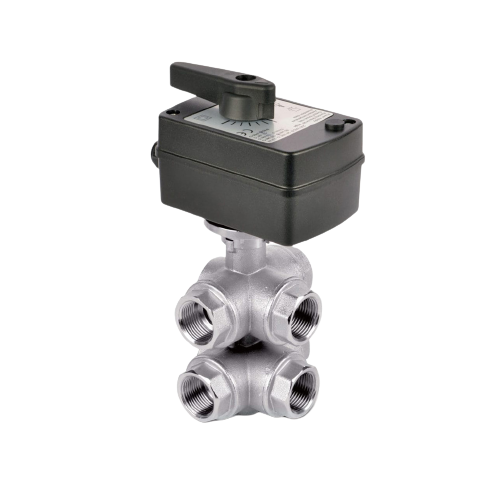

The motor-activated ball valve can be used in several sectors of installation technology. The motorized valve can be used to regulate single or multiple heating systems with alternative energy sources or systems with cold and warm fluids. It is possible to remove the servo control and operate the valve manually using an 8mm key.

The MKK valves can be installed in any position (horizontal and vertical) provided they are placed in a visible and accessible position.

Advantages of motorized ball valves:

The motor saves energy, water and time.

Valve disassembly is easy without emptying the system,

LED indicator with yellow light (When LED from ball valve closed)

When the valve closes, it does not cause water hammer

Protects the system against overload.

Technical data ball valve:

Housing: Nickel-plated brass

Ball: Chrome-plated brass

Liquid temperature: 0°C to 100°C

Working pressure: PN16

Maximum differential pressure 10 bar

Technical data Engine:

Power connection 1-4: 230 Vac or 24Vac

Protection class: IP 44

Temperature: -5°C max 55°C

Item number Description Size Voltage

KKM2133N05-230 Motorized ball valve Bu x Bu ¾" DN20 230Vac

KKM2133N06-230 Motorized ball valve Male x Male 1" DN25 230Vac

Item number Description Voltage Closing time

MT9535230 Motor 230V for MKK2133 230Vac 40sec (8Nm)

MT9535024 Motor 24V for MKK2133 24Vac 40sec (8Nm)

Item number Description Size Voltage

KKM2138N04-230 Motorized ball valve Bi x Bu 1/2" DN15 230Vac

KKM2138N05-230 Motorized ball valve Bi x Bu ¾" DN20 230Vac

KKM2138N06-230 Motorized ball valve Bi x Male 1" DN25 230Vac

KKM2138N07-230 Motorized ball valve Bi x Bu 11/4"DN32 230Vac

KKM2138N04-24 Freeze Crane Gemotor x Out 1/2" DN15 24Vac KKM2138N05-24 Freeze Crane Gemotor x Out ¾" DN20 24Vac

KKM2138N06-24 Motorized ball valve Bi x Male 1" DN25 24Vac

KKM2138N07-24 Motorized ball valve Bi x Bu 11/4"DN32 24Vac

Item number Description Voltage Closing time

MT9535230 Motor 230V for MKK2133 230Vac 40sec (8Nm)

MT9535024 Motor 24V for MKK2133 24Vac 40sec (8Nm)

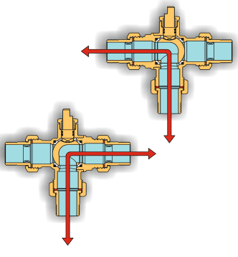

Item number Description Size Voltage

KKM2137N05-230 Motorized ball valve Bu x Bu ¾" DN20 230Vac

KKM2137N06-230 Motorized ball valve Male x Male 1" DN25 230Vac

KKM2137N05-230 Motorized ball valve Bu x Bu ¾" DN20 24Vac

KKM2137N06-230 Motorized ball valve Male x Male 1" DN25 24Vac

Item number Description Voltage Closing time

MT9536230 Motor 230V for MKK2137 230Vac 40sec (8Nm)

MT9536024 Motor 24V for MKK2137 24Vac 40sec (8Nm)

Item number Description Size Voltage

MKK2134N05-230 Motorized ball valve Bu x Bu ¾" DN20 230Vac

MKK2134N06-230 Motorized ball valve Male x Male 1" DN25 230Vac

MKK2134N05-230 Gemotorized Kogelcrane Bu x Bu 3⁄4" DN20 24Vac

MKK2134N06-230 Gemotorcircuit Kogelscrane Bu x Bu 1" DN25 24Vac

Item number Description Voltage Closing time

MT9537230 Motor 230V for MKK2134 230Vac 80sec (8Nm)

MT9537024 Motor 24V for MKK2134 24Vac 80sec (8Nm)

Item number Description Size Voltage

MKK2136N05-230 Motorized ball valve Bu x Bu ¾" DN20 230Vac

MKK2136N06-230 Motorized ball valve Male x Male 1" DN25 230Vac

MKK2136N05-24 Motorized ball valve Bu x Bu ¾" DN20 24Vac MKK2136N06-24 Motorized ball valve Bu x Bu 1" DN25 24Vac

Item number Description Voltage Closing time

MT9536230 Motor 230V for MKK2136 230Vac 40sec (8Nm)

MT9536024 Motor 24V for MKK2136 24Vac 40sec (8Nm)

Installation instructions kkm ball valves

•The valves can be installed in any position (horizontal and vertical) provided they are placed in a visible and accessible position and the opening / closing must be easy and complete.

•Other than stated, to close the valve turn the handle clockwise and counterclockwise to open it.

•If no specific markings are indicated on the valve body (arrows), there is no valve flow direction.

•The system must be designed and constructed to avoid any stress that could damage the valve/seal.

•All installation work must be carried out using correct tools.

•Connections should be such as to ensure sealing, but without any damage to the valve or fittings.

•After completing the installation, it is necessary to verify the seals according to technical specifications and/or what is required by national regulations.

•The valve should not be left in the intermediate position for a long period of time to prevent damage to the valve seals.

•If the valve has not been used for a long time, it may be difficult to operate it, so a long lever can be used.

•To keep the valve and seals in good condition, it is recommended to install a filter upstream to stop impurities.